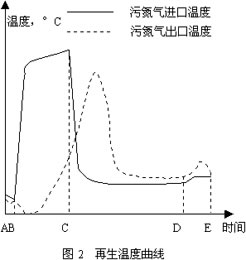

In the molecular sieve regeneration curve, temperature from pressure release starts to decline, but at the beginning of heating, temperature has minor increase, then decrease, and later it gradually increases till the end of heating.

In the molecular sieve regeneration curve, temperature from pressure release starts to decline, but at the beginning of heating, temperature has minor increase, then decrease, and later it gradually increases till the end of heating.

At the start of pressure relief, some substances which have been adsorbed by molecular sieve may occur desorption. This process need to absorb heat, and then bed temperature may decline.

At the starting period of heating, due to the regeneration temperature not high enough with unavoidable water contents, it is still exothermic adsorption process when passing through molecular sieve bed. Therefore, the temperature still needs to be slightly elevated.

After increasing air intake temperature, the molecular sieve is on the heat of desorption process. Some of heat of regenerated gas is used to heat the upper molecular sieve, while the other is absorbed by molecular sieve for desorption, which results in the gradually decreasing outlet temperature of regenerated gas in the heating stage.

When it falls to the same as the bed temperature, regenerated gas is no longer heat carrier, only providing the function as washing the molecular sieve bed of which the regeneration has been completed. Heat, stored in upper molecular sieve bed at heating period, also begins to be gradually carried out by regenerated gas. With heat penetrating the entire bed, the outlet temperature comes to lift again till the heat regeneration is completed.